|

|

|

Continuous Hinge

PLEASE SEND YOUR INQUIRIES DIRECTLY TO INFO@DELSONHINGE.COM WHILE OUR ONLINE RFQ FORMS ARE UNDERGOING MAINTENANCE.

Continuous Hinge Description

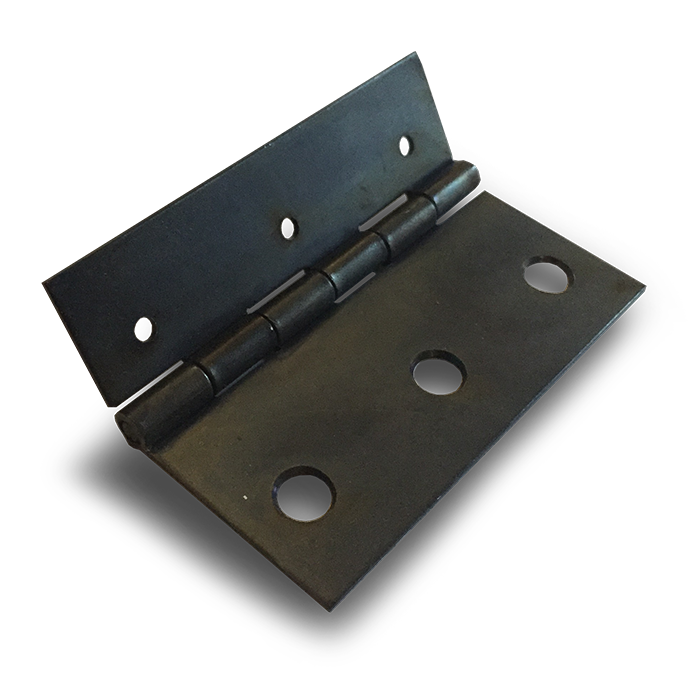

Continuous hinges are made with two independent leaves. Generally they are 6 inches or longer in length but are otherwise similar to butt type hinges.

With our extensive experience, we can provide custom hinges that meet a variety of industry specifications.

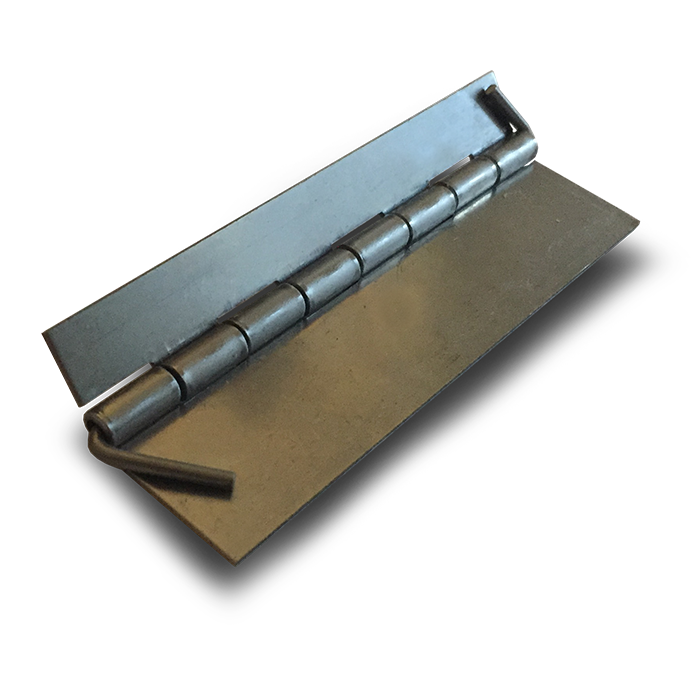

This continuous hinge is produced for a military customer to all applicable Mil-Spec standards. The hinge begins with a master coil of 0.090" thick steel. The 2.5" wide coil is cut to 35" on our cut to length line. After the blank has been cut, a 1" knuckle is stamped into the steel before it is rolled to a 1.5" centerline for each leaf. Holes are pierced according to print and pins are cut to 35" to match the hinge length. We also produce this hinge in a variety of additional lengths for this customer and are capable of modifying many standard designs to create a custom hinge for a specific application.

The final hinge is assembled and the pin is welded to the hinge

using a gas tungsten arc (TIG) welding process. The final assembly

is painted according to military specifications. Dimensional

tolerances on this hinge are held to as tight as ± 0.005" at

critical dimensions.

Military, marine and other specification grade hinges are manufactured at Delson Hinge.

| Applications |

Military, marine and custom applications |

|

| |

|

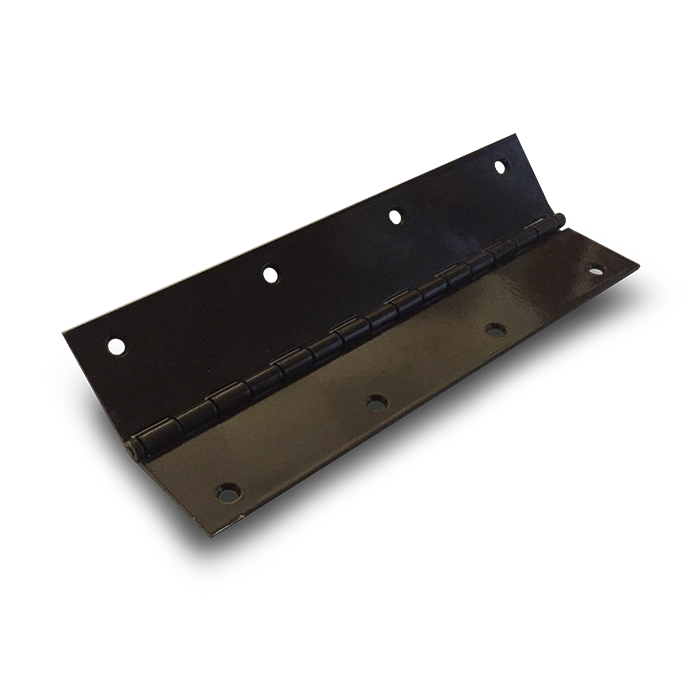

Continuous Hinge Pierced, Notched with Studs, Threading, Baked Enamel Paint

Continuous Hinge Piereced, Countersunk Holes with Closed Ends, Painted Enamel

Continuous Hinge Piereced, Countersunk with Spring Pin, Black Paint

Custom Continuous Hinge Piereced, Formed with Military Spec. Paint, Textured Finish

Custom Continuous Hinge Piereced with Black Oxide Finish

Custom Continuous Hinge with Unequal Leaves and 112° Stop Pin

Custom Continuous Hinge with Unequal Leaves and Extended Pin Steel

|

|

|

Capability Details

Click to Expand/Collapse (+)

|

| Product Description: | Custom Continuous Hinge

|

|

| Primary Capabilities Applied/Processes: | Assemble and weld pin to hinge

Blank to produce a 1 inch knuckle

Cut pins to 35 inches

Pierce to print

Roll 1 1/2" to centerline each leaf

Straighten coil and cut to 35 inches

|

|

| Equipment Used to Manufacture Part: | Cut to length line

TIG welder

Various presses and tooling

|

|

| Expertise: | Designed, built and run all tooling in house

|

|

| Overall Part Dimensions: | Steel 0.09 x 3 x 35 x 1/4 Welded pin

|

|

| Tightest Tolerances (3 place decimal): | ± 0.005

|

|

| Tightest Tolerances (2 place decimal): | ± 0.015

|

|

| Material Used: | Steel coil 0.090 x 2 1/2

|

|

| Material Finish: | Paint to Military Specifications

|

|

| In process testing/inspection performed: | Inspection is done on first piece at each operation and continuously during production run

|

|

| Industry for Use: | Military

|

|

| Volume: | 1200 Pieces per year

|

|

| Delivery/Turnaround Time: | 5 Weeks

|

|

| Delivery Location: | Bridgeport, CT

|

|

| Standards Met: | Customer Specifications

|

|

| Product Name: | Custom Hinge

|

|

|

|

|

|